Before choosing a Paint protective film product, it is necessary for you to understand some key knowledge so as to make a sensible decision. For example, is it the thicker the better? Will it turn yellow? Can it perfectly protect the car paint once applied? And does it have the scratch self-healing function?

Most PPF products on the market usually have thicknesses of 6.5mil, 7.5mil, 8.5mil, 9.5mil, etc. In fact, the thicker the PPF is not necessarily the better. Theoretically, the higher the thickness, the stronger the protective performance. However, more consideration should be given to the comprehensive performance of PPF, the materials used and their mechanical and physical properties. The PPF material mainly consists of three parts. The uppermost layer is the coating, the middle is the substrate, and the glue is in contact with the car paint. It is the middle substrate layer that truly plays the core protective role.

In the current market environment, the yellowing problem is common among TPU materials on the market, but the degree varies. Some also come with potential risks such as cracking and hydrolysis, which may even have an adverse impact on the car paint. From the perspective of chemical structure, TPU is mainly divided into two major categories: aromatic and aliphatic. Depending on the differences in the soft segment structure, TPU can be further subdivided into several types, such as polyester type, polyether type, and polycaprolactone type. Among them, the polyester, polyether, and polycaprolactone types of aromatic TPU will all show relatively serious yellowing, and over time, the impact on the aesthetics of the car paint cannot be underestimated.

As for the polyester and polyether types of aliphatic TPU, although the degree of yellowing is relatively mild, their low cost makes them often used in the production of PPF. However, this type of material has a risk of hydrolysis. Once hydrolysis occurs, it is very likely to damage the car paint. Driven by our pursuit of quality, we resolutely abandon their use. Instead, we choose relatively expensive aliphatic polycaprolactone TPU particles. The raw materials are sourced from two industry leaders, Covestro in Germany and BASF in Germany. Their products have excellent characteristics of being resistant to yellowing and hydrolysis within the shelf life, providing reliable protection for the car paint and giving you peace of mind.

In the field of high-performance substrates, Covestro’s TPU pellets and BASF’s TPU pellets have attracted much attention. Covestro’s automotive professional TPU pellet is 88395AU, which exhibits excellent mechanical properties. The combination of high strength and outstanding toughness enables it to maintain structural stability in complex environments. Likewise, BASF’s L787 also performs outstandingly, with excellent tensile strength and impact resistance, providing solid mechanical support for various applications ranging from industrial manufacturing to high-end equipment and meeting stringent mechanical requirements. We use Covestro’s 88395AU and BASF’s L787 and other automotive professional TPU pellets to produce PPF, and precisely select these two golden thicknesses of 7.5mil and 8.5mil. The reason is that 6.5MIL is too thin and the protective ability is poor; 9.5MIL is too thick and the installation is rather difficult. We deeply understand that excellent products must be paired with perfect installation effects to achieve more outstanding performance and bring you the ultimate experience.

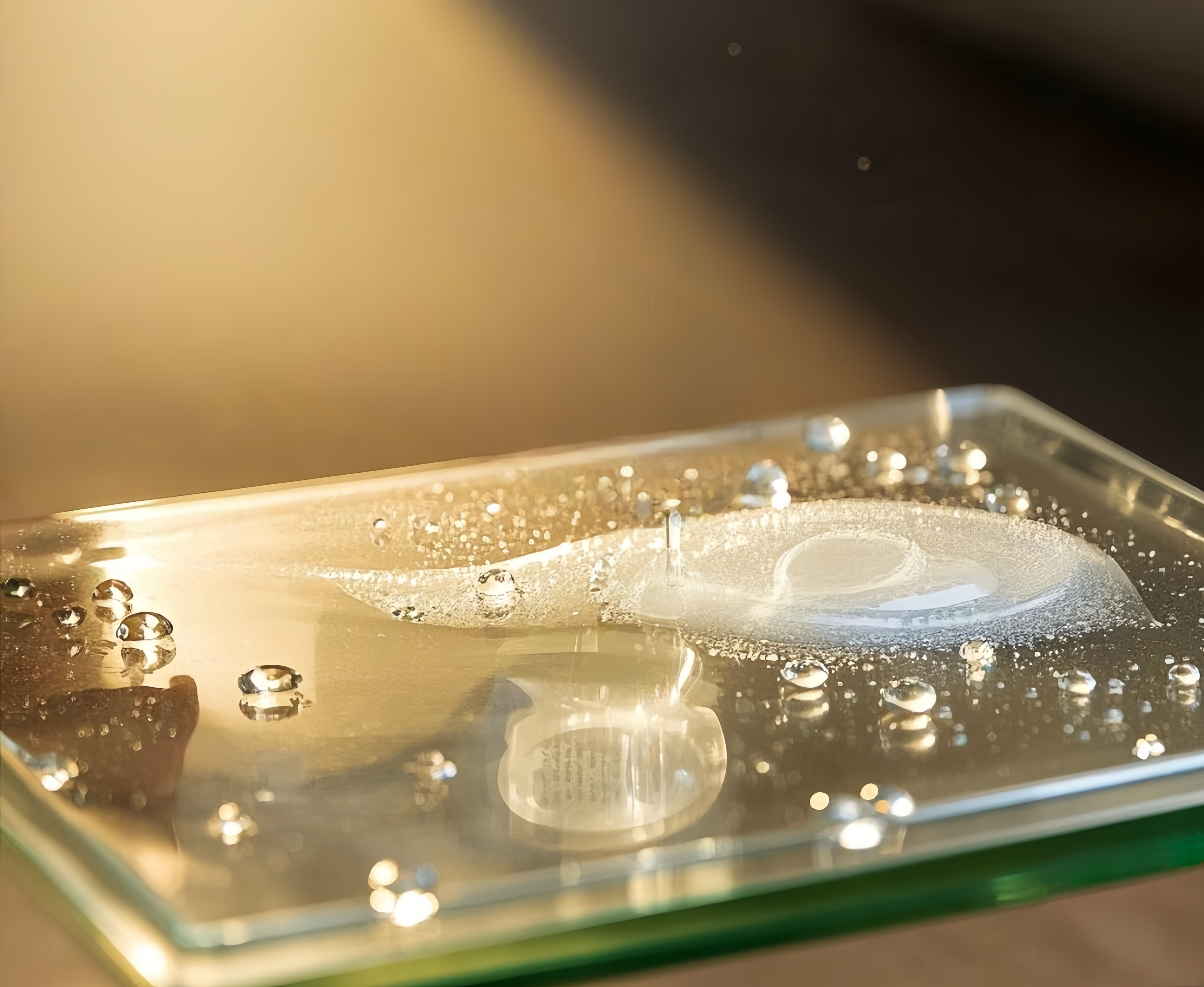

Moreover, all our PPF products incorporate the nano-level optical coating technology developed by LEV’IS Optics, are equipped with high-quality coatings from CASHEW in Japan, and use Henkel TAK8063 adhesive or Ashland 951059 adhesive. We meticulously polish every aspect, striving to maximize the potential of every bit of material and achieve a new breakthrough in product quality.

We have adopted modern technologies, namely magnetron sputtering and nano – optical processes, to replace traditional window films. By using proprietary technologies, processes and coatings, we produce high – quality and high – performance window films that reach a relatively high level of optical precision. This enables our automotive films to have high definition without distortion, and can effectively reduce energy costs, enhance privacy, ensure safety, reduce heat and glare, as well as decrease infrared penetration.

| Model | VLT | VLR | IBR(950~1400) | UVBR | TSER | Adhesion Strength | thickness | Core Technology | Abrasion Resistance |

| G80 | 76% | —% | 92% | 99% | 38%≈43% | — N/mm | 2mil | Nano ceramics | — % |

| G70 | 76% | —% | 93% | 99.68% | 38%≈44% | — N/mm | 2mil | Nano ceramics | — % |

| G50 | 49% | —% | 93% | 99.68% | 40%≈44% | — N/mm | 2mil | Nano ceramics | — % |

| G35 | 36% | —% | 94% | 99% | 41%≈51% | — N/mm | 2mil | Nano ceramics | — % |

| G15 | 16% | —% | 93% | 99% | 44%≈54% | — N/mm | 2mil | Nano ceramics | — % |

| G05 | 5% | —% | 93% | 99% | 51%≈57% | — N/mm | 2mil | Nano ceramics | — % |

| Model | VLT | VLR | IBR(950~1400) | UVBR | TSER | Adhesion Strength | thickness | Core Technology | Abrasion Resistance |

| M80 | 76% | 8% | 94% | 99% | 43%≈49% | 26N/25mm | 3mil | Nano-ceramic magnetron sputtering | 2.00% |

| M70 | 76% | 8% | 92% | 99.89% | 44%≈49% | 27N/25mm | 3mil | Nano-ceramic magnetron sputtering | 2.00% |

| M50 | 50% | 6% | 94% | 99% | 44%≈51% | 26N/25mm | 3mi | Nano-ceramic magnetron sputtering | 2.30% |

| M35 | 35% | 5.70% | 95% | 99% | 50%≈60% | 27N/25mm | 3mil | Nano-ceramic magnetron sputtering | 2.00% |

| M25 | 25% | 5.20% | 92% | 99% | 50%≈61% | 27N/25mm | 3mil | Nano-ceramic magnetron sputtering | 2.60% |

| M15 | 15% | 5.40% | 93% | 99% | 54%≈66% | 27N/25mm | 3mil | Nano-ceramic magnetron sputtering | 3.30% |

| M10 | 10% | 4.90% | 95% | 99% | 57%≈67% | 27N/25mm | 3mil | Nano-ceramic magnetron sputtering | 3.30% |

| M05 | 5% | 4.90% | 95% | 99% | 58%≈69% | 30N/25mm | 3mil | Nano-ceramic magnetron sputtering | 3.30% |

| Model | VLT | VLR | IBR(950~1400) | UVBR | TSER | Adhesion Strength | thickness | Core Technology | Abrasion Resistance |

| VL70ZC | 71% | 9% | 89% | 99.24% | 54%≈58% | 11/25 N/mm | 1.5mil | Single-layer metal magnetron sputtering | 1.50% |

| VL55ZC | 57% | 8% | 92% | 99.24% | 54%≈60% | 13/25 N/mm | 1.5mil | Single-layer metal magnetron sputtering | 1.50% |

| VL40ZC | 46% | 10% | 91% | 99.24% | 57%≈62% | 12/25 N/mm | 1.5mil | Single-layer metal magnetron sputtering | 1.50% |

| VL25ZC | 28% | 10% | 96% | 99.24% | 64%≈68% | 11/25 N/mm | 1.5mil | Single-layer metal magnetron sputtering | 1.50% |

| Model | VLT | VLR | IBR(950~1400) | UVBR | TSER | Adhesion Strength | thickness | Core Technology | Abrasion Resistance |

| LXR70 | 71.40% | 8.70% | 95% | 99.60% | 58%≈66% | 12/25 N/mm | 3mil | 12 – layer precious – metal magnetron sputtering | 2.10% |

| LXR40 | 45.70% | 7.50% | 97% | 99.85% | 62%≈67% | 14/25 N/mm | 3mil | 12 – layer precious – metal magnetron sputtering | 2.00% |

| LXR25 | 25.10% | 5.80% | 97% | 99.91% | 66%≈69% | 14/25 N/mm | 3mil | 12 – layer precious – metal magnetron sputtering | 2.00% |

Address: 26850 E US 380 #2201, Aubrey, TX 76227

Phone:+1(323)942-7561

+1(323)942-7561

ScottNoles@gmail.com

© 2024 LEVIS OPTICAL TECHNOLOGY (TX) CO., LTD All Rights Reserved